At Unique Hose Reel, our Tank Manifold Systems are more than just components — they’re the backbone of efficient, safe, and high-performance fuel delivery operations throughout Mississauga, Toronto, Oakville and the Greater Toronto Area (GTA). Built for demanding environments, these systems combine precision engineering with practical design to help fleets and fuel service providers deliver fuel faster, cleaner, and smarter than ever before.

What Are Tank Manifold Systems?

A tank manifold system is a centralized assembly of valves, galleries, and connection points engineered to control and distribute fuel from multiple compartments on tanker trucks or bulk storage tanks. Unlike traditional setups that rely on a bunch of adapters, jumper hoses, and manual hookups, a manifold system simplifies fuel flow paths — minimizing human error and maximizing operational output.

Technically Speaking — How They Work

At their core, tank manifold systems allow operators to:

- Select and isolate individual fuel compartments

- Manage multi-product deliveries with precision

- Integrate with pump systems for bottom loading or gravity unloading

- Operate valves mechanically or via air-activated systems for consistent and reliable opening/closing cycles.

Systems with air-activated manifold chambers use double-acting cylinders and closed-loop pneumatics to prevent debris entry and ensure smooth valve action under harsh field conditions. Independent manifold galleries allow operators to service two different fuel types from the same vehicle, improving versatility.

Why Tank Manifold Systems Are Essential for Fuel Delivery in Toronto and the GTA?

Whether you’re servicing highways around Mississauga, industrial sites in Toronto, or construction fleets in Oakville, a robust fuel delivery manifold offers measurable advantages:

Increased Productivity: Tank manifolds eliminate the need for multiple hoses, adapters, and temporary connections — cutting setup time and reducing manual intervention. This means faster service cycles and more deliveries per shift.

Enhanced Safety & Spill Reduction: By centralizing connections and reducing loose fittings, manifold systems decrease the risk of spills, leaks, and trip hazards — key concerns in fuel delivery operations regulated under stringent safety standards.

Lower Risk of Product Cross Contamination: Precision valve design and compartment isolation capabilities ensure that distinct fuels don’t mix — a critical benefit when handling gasoline, diesel, or bio-blend fuels across multi-compartment tankers.

Compact, Controlled Flow Paths: Technical manifold designs reduce the number of junctions and potential leak points in the system. Shorter and simplified fluid pathways also mean lower pressure losses and improved flow control during pumping operations.

Compliance & Operational Control: High-quality manifolds offer better monitoring and flow regulation, helping fleets meet operational standards, regulatory compliance, and reporting accuracy — from fuel depot to end user.

Technical Benefits That Customers Love

Here’s what advanced manifold technology delivers on a deeper level:

Minimal Setup Complexity — Systems are factory-assembled, reducing field assembly times and installation errors.

Parallel Operations — Some manifold architectures support simultaneous multi-compartment deliveries, increasing throughput.

Automated Cross-Over Prevention — Smart manifold designs include safety logic that stops deliveries if improper configurations are detected.

Expanded Flow Capacity — Properly engineered manifolds maintain high flow rates while reducing back pressure and ensuring consistent fuel delivery.

Proudly Serving Ontario’s Fuel Delivery Industry

Unique Hose Reel’s tank manifold systems are engineered and specifically optimized for fuel distributors, petrochemical fleets, logistics providers, and while we service companies in Mississauga, Toronto, Oakville and the GTA, we are a worldwide distributor of hose reels, tank manifold systems and industrial valves. Our systems are rugged, configurable, and designed to match the real-world challenges of today’s fuel delivery landscape.

Built for Performance — Designed for Productivity

From single-bank manifolds to dual-bank and Uniflow configurations, our tank manifold systems adapt to trucks hauling multi-compartment payloads. Options include:

- Stainless steel and aluminium construction

- Mechanical or air-activated controls

- Bottom loading, gravity unloading, and product return compatibility

- Sizes ranging from 3″ to 4″ ports and beyond

- Customized configurations on request

This adaptability makes our manifolds a perfect choice for fleet operators who demand precision, safety, and reliability on every delivery — whether it’s gasoline at a service station or diesel to a construction site.

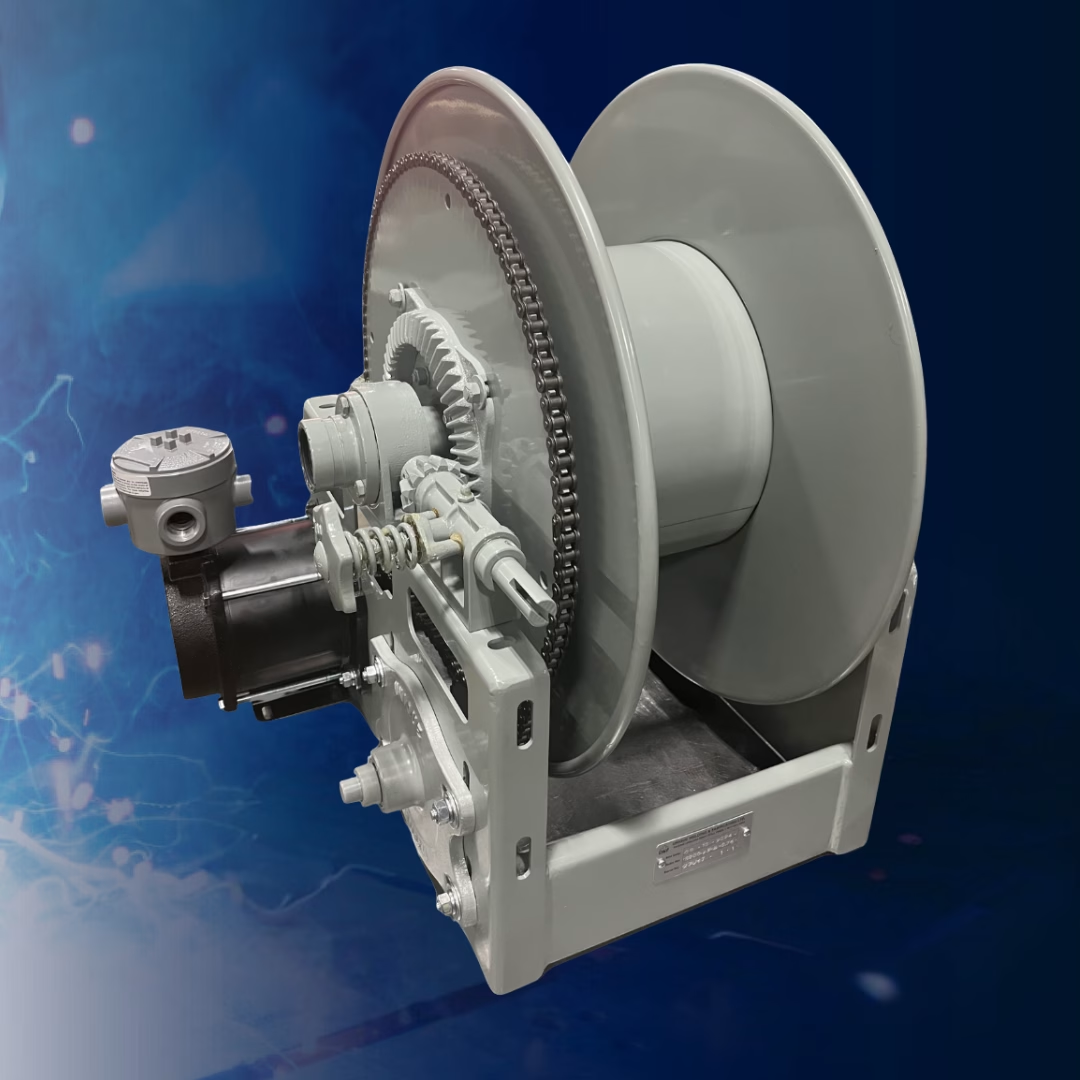

Beyond Manifolds — Complete Fuel Delivery Solutions

At Unique Hose Reel, we don’t stop with manifolds. We also provide a full suite of hose reels, industrial valves, and replacement parts designed to keep your fuel delivery ecosystem operating at peak performance. Whether it’s a new installation or an upgrade, we deliver engineered solutions that work as hard as you do.