The type of reel you need is determined by two factors – what it’s holding (hose or cable) and how it will be used (live or storage).

Hose Reels vs. Cable Reels

Start with the hose or cable you’ll be using. The size, length, and type are the primary factors in selecting the proper reel for your job, but the quality of the hose or cable is just as important.

- Hose Quality. Be sure to use good quality hose rated for the service and operating pressures and temperatures to perform your application safely and efficiently. Poor quality hose tends to expand and contract under pressure surges, causing the reel to bind or even become distorted and inoperable. Check for proper temperature and pressure ratings and compatibility with the fluid you will be using whether it be fuel, corrosive chemicals, pesticides or water.

- Cable Quality. It is important to use good quality cable, properly sized, with the correct number and size of conductors to carry the required amperage and voltage. Compliance with local electrical codes should also be considered.

Live Reels vs. Storage Reels

Live reels connect to your hose or cable, allowing fluid or current to pass through while still on the reel.

- Continuous-Flow Hose Reels come as live single hose reels or live dual hose reels and are built to specifically handle a variety of liquids and gases.

- Live Electric Cable Reels can be customized based on the number of conductors and connectors, voltage, amperage, and cable specifications for your situation.

Storage reels wind up your hose or cable, but do NOT allow fluid or current to flow while still on the reel. The hose or cable must be taken off the spool of the reel to be connected and used.

Investing in a hose reel offers numerous benefits, from improved organization and safety to enhanced functionality and hose longevity. Whether for residential, commercial, or industrial use, a hose reel is a practical and efficient solution for managing hoses and ensuring they remain in optimal condition.

How Do I Select the Right Reel Model?

Once you know what type of reel you need (hose vs. cable, live vs. storage), it’s important to understand the available options and your specific needs to ensure a perfect fit.

Reel Options:

Unique Hose Reels offers a variety of options:

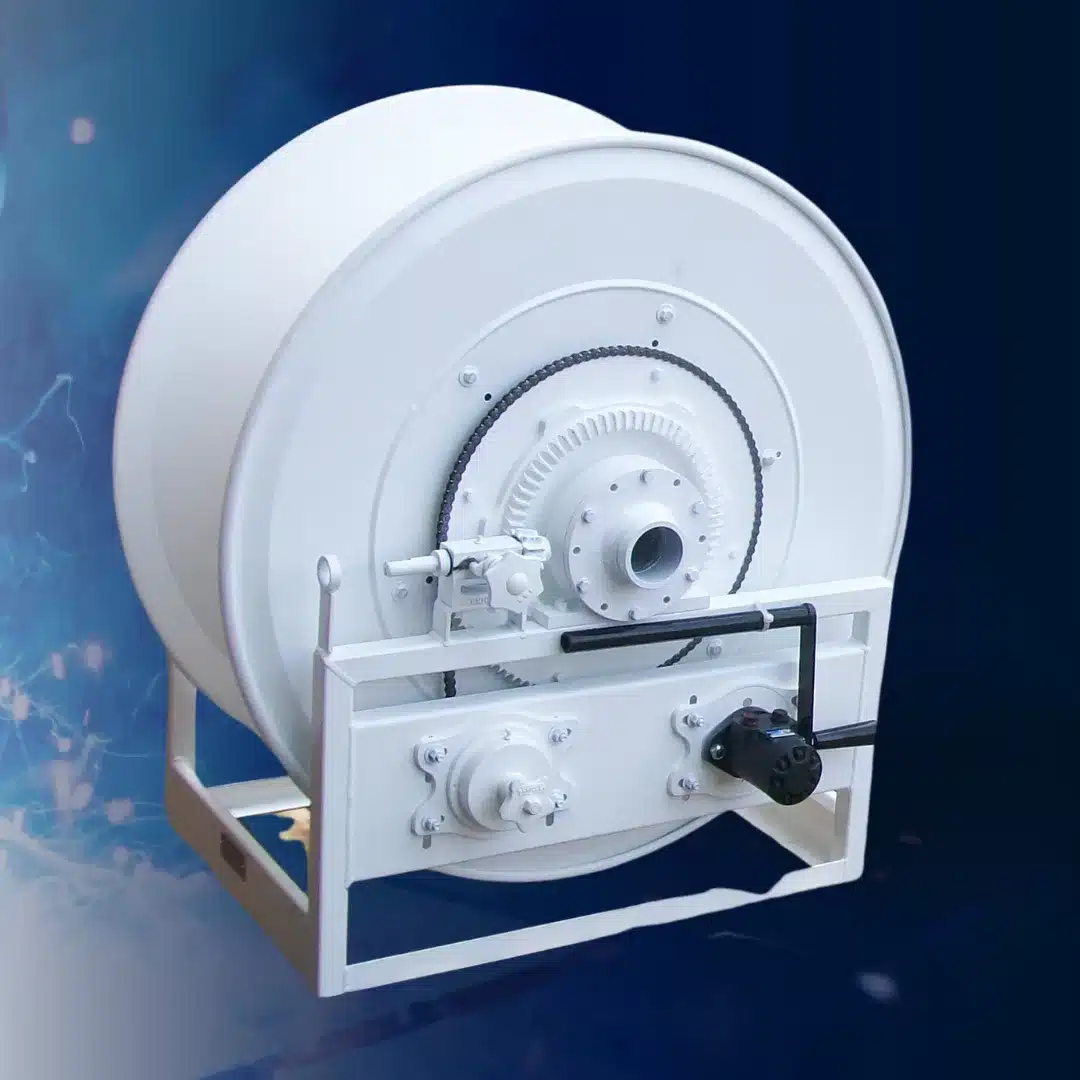

- Construction: Frames, discs, and drum are fabricated of heavy-gauge steel. Bearings are self-aligning.

- Hose Reel Construction: Malleable iron and steel are used for hose reel hub assembly, outlet riser, and swivel joints. Stainless steel, aluminum, and special swivel joint packing can be supplied to meet special requirements.

- Cable Reel Construction: Collector ring housings are ABS plastic or insulated steel, depending on model.

- Finish: Standard finish is oven-cured enamel. Finishes other than standard, such as special primers, may be specified at an additional cost.

- Accessories: Add more features to your reel, including:

- Brakes and locks

- RCB kits and switches

- Operating switches and speed controls for electric rewind reels

- Circuit breakers

- Rewind assemblies for gear-driven crank rewind reels

- Clutch and reduction assemblies

- Hose and cable stops

- Hose assemblies

- Roller assemblies for spring rewind reels

Industrial hose and cable reels are essential equipment used to store, manage, and extend hoses or cables in various industrial settings. There are several types of hose and cable reels designed for different applications. Here are some of the main types:

1. Spring-Driven Hose and Cable Reels

- Description: These reels use a spring-loaded mechanism to retract the hose or cable automatically.

- Applications: Common in environments where frequent hose/cable use is needed but manual winding is impractical.

- Advantages: Self-retracting, reducing trip hazards and preventing tangling.

- Types:

- Air Hose Reels: Used to store air hoses, common in workshops, garages, or factories.

- Water Hose Reels: For storing water hoses in industrial or agricultural applications.

2. Manual Hose and Cable Reels

- Description: These reels require manual effort to wind the hose or cable back onto the reel.

- Applications: Often used for lighter-duty hoses or cables.

- Advantages: Lower cost and more control over the winding process.

- Types:

- Hand Crank Reels: These are turned by hand, ideal for lighter hoses and cables.

- Wall-Mounted Reels: Fixed in place and used for light to medium duty hoses or cables.

3. Motorized Hose and Cable Reels

- Description: Powered by an electric motor to retract the hose or cable with minimal effort from the operator.

- Applications: Suitable for environments with heavy or long hoses and frequent use.

- Advantages: High efficiency, especially for larger, more robust hoses.

- Types:

- Electric Motor-Driven: Electric motor drives the retraction of the hose or cable.

- Pneumatic Motor-Driven: Uses compressed air to retract hoses, often found in industrial settings.

4. Heavy-Duty Hose and Cable Reels

- Description: Designed for high-pressure, high-volume hoses or large cables in demanding environments.

- Applications: Common in construction sites, manufacturing plants, and large workshops.

- Advantages: Durable construction, designed for continuous heavy use.

- Types:

- High-Pressure Hose Reels: Used for hoses that handle high-pressure fluids.

- Cable Reels for Power Cables: Designed to handle large power cables, such as for cranes, or heavy machinery.

5. Portable Hose and Cable Reels

- Description: These reels are designed to be mobile and easy to move from one location to another.

- Applications: Ideal for environments where hoses or cables are used in different areas.

- Advantages: Flexibility and convenience in moving equipment.

- Types:

- Trolley Reels: Mounted on wheels, these are easy to move around work areas.

- Compact Handheld Reels: Small, portable reels for light hoses or cables.

6. Retractable Hose and Cable Reels

- Description: Similar to spring-driven reels but with more advanced retraction mechanisms, often designed for quick, automatic retraction.

- Applications: Suitable for environments with limited space and a need for quick hose or cable storage.

- Advantages: Space-saving and reduces the potential for damage or tangling.

- Types:

- Automatic Retracting Reels: Use springs, motors, or pneumatic systems for automatic retraction.

7. Floor-Mounted Hose and Cable Reels

- Description: These reels are mounted directly to the floor, providing a stable base for winding and unwinding hoses or cables.

- Applications: Often used in large factories or workshops where hose use is frequent.

- Advantages: Stable and durable for heavy-duty use.

- Types:

- Fixed Base: Permanently fixed to the floor.

- Adjustable Base: Can be adjusted for different working environments.

8. Wall-Mounted Hose and Cable Reels

- Description: These are fixed to the wall to save floor space.

- Applications: Common in areas where space is limited or where hoses/cables need to be out of the way when not in use.

- Advantages: Space-saving, easily accessible.

- Types:

- Horizontal Mount: Mounted horizontally on the wall.

- Vertical Mount: Mounted vertically to take up less horizontal space.

9. Dual Hose and Cable Reels

- Description: Designed to handle two separate hoses or cables at the same time.

- Applications: Used in environments where two different types of hoses or cables are required to be used simultaneously.

- Advantages: Allows easy access to multiple hoses or cables from a single reel.

- Types:

- Two Separate Compartments: Each compartment can hold a different hose or cable.

10. Custom Hose and Cable Reels

- Description: These are tailored to specific needs, often for unique hoses or cables in specialized industries.

- Applications: Custom-designed for non-standard hose or cable sizes.

- Advantages: Flexibility to handle unique requirements.

- Types:

- Corrosion-Resistant Reels: Made from materials that resist rust or corrosion for use in harsh environments like marine or chemical industries.

Each type of reel serves different needs based on the application, frequency of use, hose or cable length, and environment. Choosing the right reel ensures efficiency, safety, and longevity of the hose or cable being used.

Ordering Your Hose or Cable Reel

Before placing your order, please consider the following specifications for your cable or hose:

- Hose Specifications: Type (single or dual), internal diameter (I.D.), length, bend radius, and operating temperature and pressure of hose contents and what fluid you will be running through it.

- Cable Specifications: Outside diameter (O.D.), length, bend radius, number of conductors, and amperage/voltage needed for your application.

When space permits, select a reel with greater capacity than what is actually needed. This allows you to rewind with less care and keeps the hose or cable well protected, even if it is not wound in uniform coils. In most cases, the larger reel within the same series is the same price.